Casual Tips About How Much Is 7nm Torque

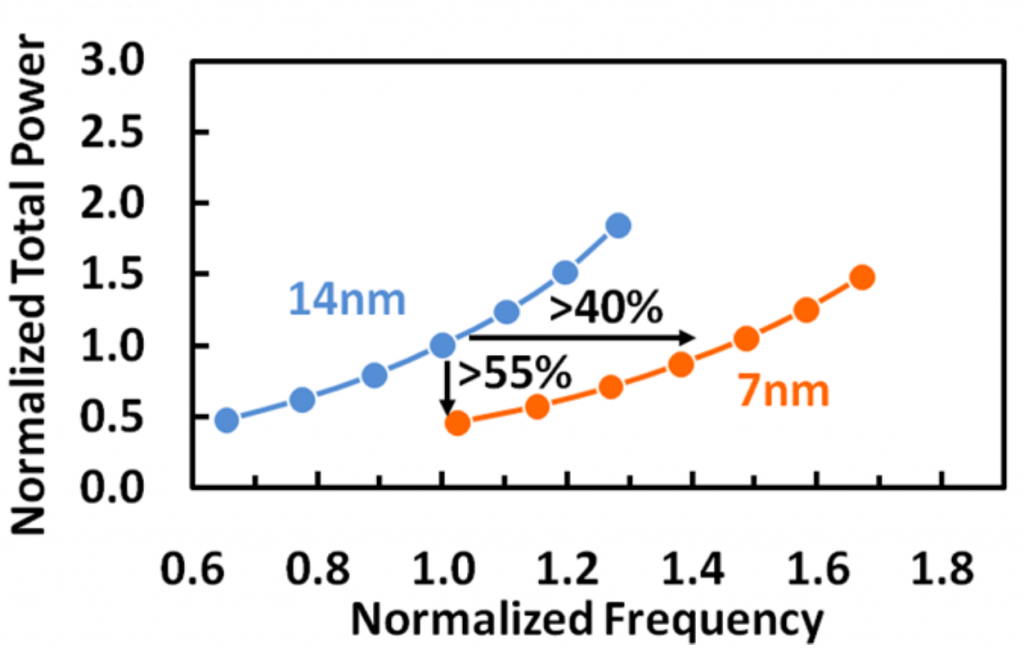

GlobalFoundries' 7nm Process Is Set To Make Intel's Leadership

Understanding Torque

1. What Exactly is Torque Anyway?

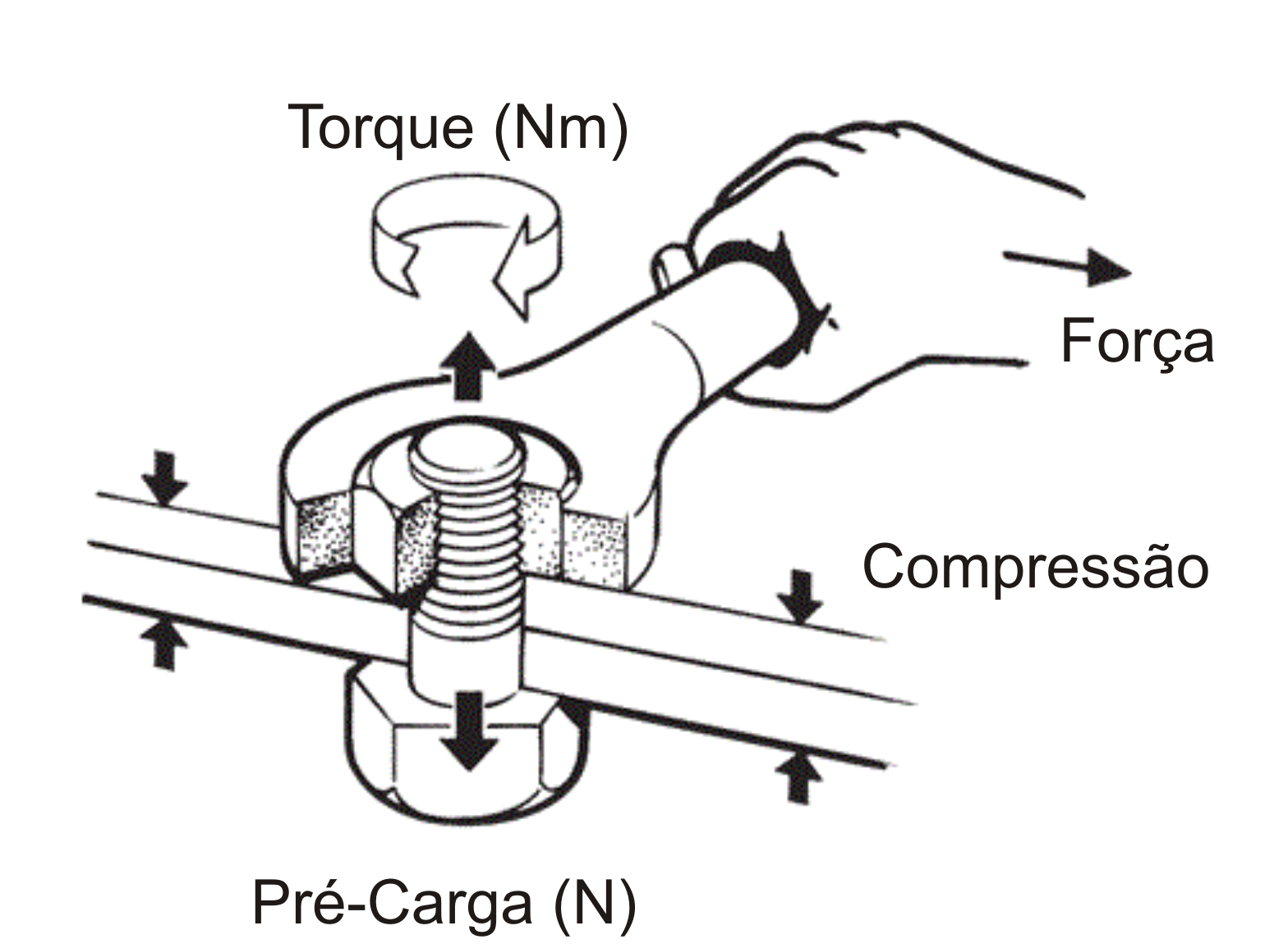

Ever wondered what that 'Nm' number on your wrench means? Well, buckle up, because we're diving into the world of torque! Simply put, torque is a twisting force that causes rotation. Think of it like trying to open a stubborn jar lid. The effort you put into twisting the lid is torque. It's measured in Newton-meters (Nm), which essentially tells you how much force you're applying at a certain distance from the center of rotation.

So, that "7 Nm" we're talking about? It's a specific amount of this twisting force. Imagine attaching a wrench that's one meter long to a bolt, and then applying 7 Newtons of force to the end of the wrench. That's 7 Nm of torque! In the real world, wrenches are usually shorter, so you need to apply more force to achieve the same torque.

Why is torque so important? Because it ensures things are properly tightened! Too little torque, and your bolt might come loose, leading to all sorts of problems (like a wobbly wheel on your car!). Too much torque, and you risk stripping the threads or even breaking the bolt. Finding that sweet spot is key.

Torque is a concept that is used everywhere! It's is not just for mechanics, it's a fundamental principle in physics and engineering that plays a crucial role in countless applications. From the tiny screws in your eyeglasses to the massive bolts holding skyscrapers together, torque is the silent hero ensuring everything stays put.

2. 7 Nm

Now, let's get down to brass tacks: how much is 7 Nm, really? It's not a huge amount, but it's enough to be significant in certain situations. Think of delicate electronics, small engines, or even bicycles. Over tightening nuts and bolts in that setting can result in damaging these parts.

Imagine tightening the screws on a bicycle's handlebar stem. You wouldn't want to crank down on them with all your might, right? That's where a torque wrench set to 7 Nm comes in handy. It allows you to apply just the right amount of force, preventing damage to the components and ensuring a secure fit.

Many smaller components on vehicles, such as interior trim panels or sensors, might require a 7 Nm torque setting. Ignoring the correct torque and going by "feel" can lead to cracked plastic, stripped threads, or even electrical malfunctions. Precision is paramount!

Think of the little screws that hold together your glasses. They're tiny, right? Applying even a little bit too much force can strip the head or even break the frame. A small amount of torque is all that is needed in some instances. 7 Nm is a great example of a precise unit of torque.

Where You'll Find 7 Nm Torque in Action

3. Bicycles and Beyond

Alright, where exactly might you encounter this magical 7 Nm torque in your everyday life? Bicycles are a prime example. Many components, like handlebar clamps, seat post clamps, and even some brake lever bolts, require a specific torque around 7 Nm.

Another area is in electronics. When working with circuit boards or assembling small electronic devices, over-tightening screws can easily damage delicate components. A 7 Nm torque setting can be ideal for securing these screws without causing any harm.

Some household appliances might also have components that require this level of torque. Think of small motors or control panels that need to be securely fastened without being overstressed. Even certain toys and models might specify a 7 Nm torque setting for assembly.

Automotive applications also utilize 7nm torque! While larger bolts on a car's engine or suspension system require significantly more torque, smaller components like sensors, interior trim pieces, and even some electrical connectors might call for this precise level of tightness.

4. Tools of the Trade

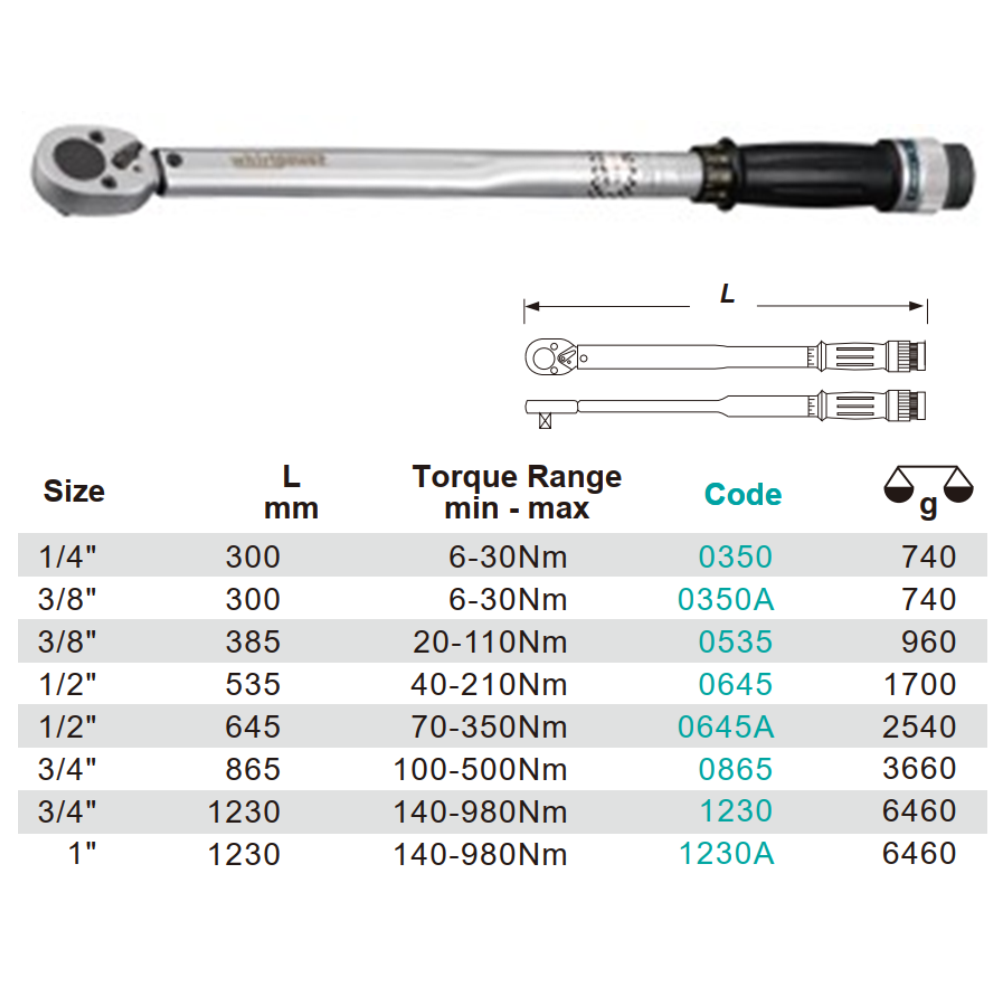

So, how do you actually apply 7 Nm of torque reliably? You're not just going to guess, are you? That's where a torque wrench comes in. These specialized wrenches are designed to measure and control the amount of torque applied to a fastener.

There are different types of torque wrenches, from the simple beam type to the more sophisticated digital models. The best choice for you will depend on your needs and budget. For occasional use, a beam-type wrench might be sufficient. But for more demanding applications, a click-type or digital wrench is recommended.

No matter what type of torque wrench you choose, it's crucial to calibrate it regularly. Over time, torque wrenches can lose their accuracy, leading to incorrect torque readings. A properly calibrated wrench ensures you're applying the exact amount of torque specified by the manufacturer.

Using a torque wrench isn't just about getting the right number; it's about preventing damage and ensuring safety. Whether you're working on your bicycle, assembling electronics, or servicing your car, using a torque wrench is a smart investment that can save you time, money, and frustration in the long run.

Why Precise Torque Matters

5. The Consequences of Overtightening (and Undertightening!)

What happens if you ignore the torque specifications and just tighten things until they "feel" right? Well, you're playing a risky game! Overtightening can lead to stripped threads, broken bolts, and damaged components. Imagine cracking a plastic part because you were too eager to tighten a screw. Not fun, right?

Undertightening, on the other hand, is equally problematic. If a bolt isn't tight enough, it can come loose over time, leading to vibrations, instability, and even catastrophic failure. Think of a wobbly wheel on your car — not something you want to experience at high speed!

Proper torque ensures that fasteners are tightened to the correct tension, creating a secure and reliable connection. This is especially important in applications where safety is critical, such as automotive, aerospace, and medical equipment.

The consequences of incorrect torque can range from minor inconveniences to serious accidents. By taking the time to learn about torque and use the correct tools, you can avoid these problems and ensure that your projects are safe and reliable.

Torque Wrench Socket Sizes At Anthony Sears Blog

Frequently Asked Questions (FAQ)

6. Your Torque Questions Answered

Okay, let's tackle some common questions about torque. You're probably wondering things like, "How do I convert Nm to other units?" and "What if I don't have a torque wrench?" Let's get those answered.

7. Q

A: Converting between different torque units is actually pretty straightforward. To convert from Newton-meters (Nm) to foot-pounds (ft-lbs), you can use the conversion factor: 1 Nm 0.7376 ft-lbs. So, 7 Nm would be approximately 5.16 ft-lbs. For inch-pounds (in-lbs), use the conversion factor: 1 Nm 8.85 in-lbs. Therefore, 7 Nm is roughly 61.95 in-lbs. There are plenty of online conversion tools that can do the math for you if you don't want to do it by hand!

8. Q

A: While it's always best to use a torque wrench for accurate results, there are some cases where you can get by without one. However, it requires a good understanding of fastener tension and "feel," which comes with experience. You could try using a regular wrench and estimating the force you're applying, but this is not recommended for critical applications where precise torque is essential. Consider borrowing or renting a torque wrench if possible.

9. Q

A: As a general guideline, smaller fasteners and softer materials usually require less torque. For instance, when working with plastic or aluminum, be extra cautious not to overtighten. Look for visual cues like the fastener slightly compressing the material, but stop before it starts to deform. If you have access to similar applications with torque specifications, use that as a reference point. However, when in doubt, always consult the manufacturer's specifications or seek advice from a qualified professional.

O Que é A Medida Nm De Torque?