Brilliant Tips About What Is PCB Vs PWB CCA

PWB Vs PCB A Deep Comparison Of Both Boards Hillman, 57 OFF

Decoding the Circuit Board Alphabet Soup

1. Understanding the Basics

Ever stared at the guts of your computer or smartphone and wondered about that green (or sometimes blue, red, or even black!) board with all the tiny components? Well, that's likely a circuit board, and you've stumbled into the world of acronyms! Specifically, PCB, PWB, and CCA. Don't worry, we're here to unravel this alphabet soup. Think of it like learning a new language — a language spoken by engineers, robots, and, well, your washing machine.

At their core, these terms describe different stages and aspects of the same thing: a platform for connecting electronic components. It's all about how youre referring to it. Are you talking about the bare bones structure? Or the fully populated, ready-to-rock assembly? The key is context. It's like the difference between a house's foundation, the walls, and the furnished living room.

This isnt just about semantics, though. Understanding the nuances between PCB, PWB, and CCA can be helpful in engineering, manufacturing, and even troubleshooting electronic devices. Especially when communicating with technical people. So, lets break down each term and see what makes them unique (and, okay, a little bit confusing).

Well start by tackling the most common term, the one youve probably heard the most: PCB. Then, well delve into the world of PWBs and CCAs and their particular significance. Along the way, we'll uncover the subtle but crucial distinctions that will enable you to confidently navigate the realm of electronics manufacturing lingo.

PCB

2. Printed Circuit Board Defined

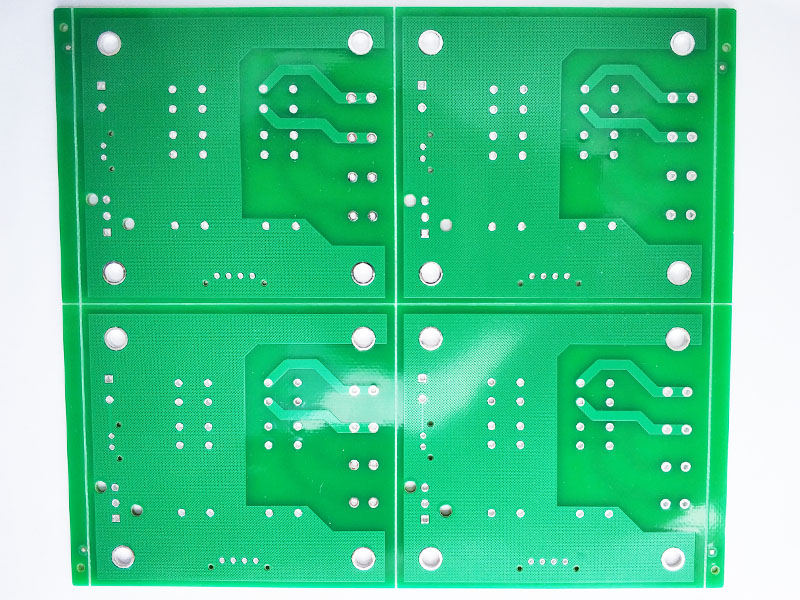

PCB stands for Printed Circuit Board. This is the most fundamental term. Think of it as the substrate, the base material upon which everything else is built. It's a non-conductive board (usually made of fiberglass epoxy, or similar material) with conductive pathways, tracks, or traces etched onto its surface. These traces are usually made of copper and act as wires, connecting electronic components together. The PCB is the noun here, the core object we're talking about. The "printed" refers to the manufacturing process used to create those conductive pathways, although modern techniques often involve etching rather than literal printing.

Imagine a city's road network. The PCB is like the map of those roads, showing where each street connects to another. Without the roads, the city would be a chaotic mess. Similarly, without the PCB, electronic components would be a jumbled pile of wires, unable to function correctly. It offers a consistent, dependable platform for assembling electrical circuits.

PCBs can be single-sided (traces on one side only), double-sided (traces on both sides), or multi-layered (multiple layers of traces sandwiched together). The complexity of the PCB depends on the complexity of the circuit it needs to support. A simple PCB might have only a few components and traces, while a complex PCB might have thousands of components and traces on multiple layers.

The key takeaway? A PCB is the bare, unpopulated board. It's the canvas before the artist starts painting. It's the foundation before the house is built. It's the framework upon which all electronic wonders are built. Now, let's move onto PWB which is very similar!

PWB

3. Understanding the Nuances of PWB

PWB stands for Printed Wiring Board. Here's where things get a little interesting. The terms PCB and PWB are often used interchangeably, and in most contexts, that's perfectly fine. However, purists (and some standards organizations) will argue there's a subtle distinction. While a PCB implies any board with printed circuitry, a PWB specifically refers to a board that only provides interconnection. The keyword here is "wiring". The PWB emphasizes the interconnectivity aspect.

Think of it this way: A PCB is the generic term, encompassing any board with printed circuitry. A PWB is a specific type of PCB, one designed primarily for wiring and connecting components. In the really old days (like, vacuum tube era), components were often wired point-to-point. The PWB was an advancement that provided a more structured and reliable way to wire components together, and the term has somewhat stuck around.

While the industry is moving towards using PCB more universally, recognizing the term PWB is important, particularly when dealing with older documentation or specific industry standards. So, when you see PWB, think "printed circuit board focused on wiring and interconnections." Its like distinguishing between a car and a sports car both are cars, but one is a specific type with enhanced performance.

In practical terms, the difference is often negligible. Modern PCBs almost always incorporate both component mounting and interconnection functions. So, don't sweat it too much if you hear either term being used. Just know that a PWB is essentially a PCB with a strong emphasis on the wiring and interconnection aspect.

CCA

4. From Bare Board to Functional Unit

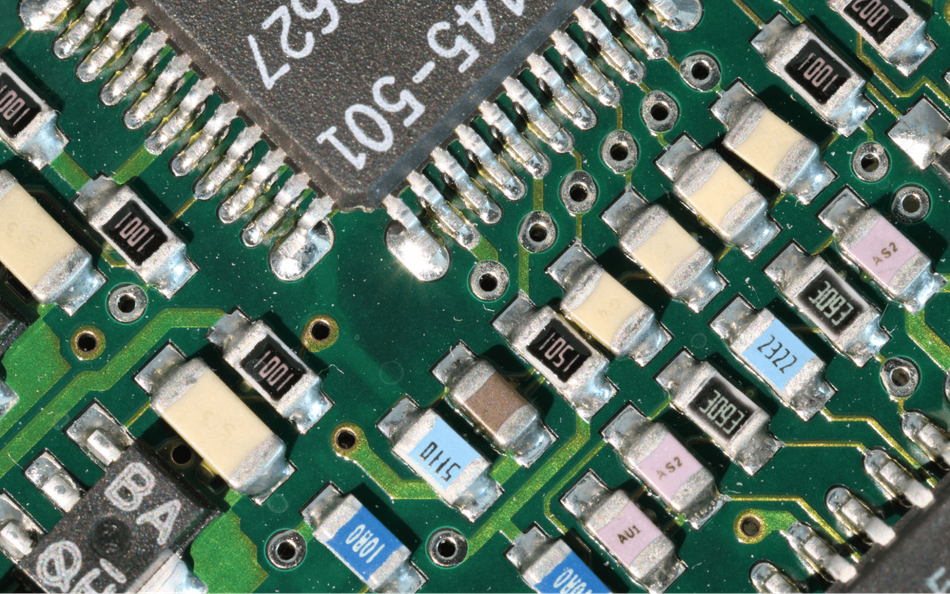

CCA stands for Circuit Card Assembly. This is where the magic truly happens! The CCA represents the PCB (or PWB) after all the electronic components have been mounted, soldered, and connected. It's the finished product, the fully populated board ready to be plugged into a device and perform its intended function. The CCA represents the populated state of the board.

Going back to our house analogy, the CCA is like the fully furnished house, complete with furniture, appliances, and decorations. It's no longer just a structure; it's a functional living space. Similarly, the CCA is no longer just a bare board; it's a functional electronic circuit.

A CCA can range from a simple circuit with just a few components to a complex assembly with thousands of components, including integrated circuits (ICs), resistors, capacitors, and connectors. The manufacturing process of a CCA involves sophisticated equipment and techniques, including automated component placement, soldering, and testing. Failure to properly assemble a CCA can lead to malfunctions and even damage to the connected device.

So, when you encounter the term CCA, picture a complete, functional circuit board, ready to power your gadgets, control your appliances, or even guide a rocket to the moon. It's the culmination of design, manufacturing, and engineering expertise, all coming together on a single board.

Bringing It All Together

5. From Concept to Reality

Now that we've explored each term individually, let's visualize how they fit together in the lifecycle of a circuit board. It's a bit like a caterpillar transforming into a butterfly. The process starts with a design, which is then translated into a PCB (or PWB) layout. This layout specifies the location of components and the routing of traces.

Next, the bare PCB is manufactured. This involves etching the conductive traces onto the board and drilling holes for component leads. Once the PCB is ready, the components are placed onto the board and soldered into place. This process can be done manually or using automated equipment. The result is a CCA, a fully populated circuit board ready for testing and integration into a larger system.

Think of it like baking a cake. The PCB is like the empty cake pan. The PWB is like the cake pan with the design of where the cake batter should go to evenly spread. The CCA is like the finished cake, complete with frosting, decorations, and ready to be eaten (or, in the case of a circuit board, ready to power your electronics!). This transition from bare board to functional assembly represents the journey from concept to reality, showcasing the interconnectedness of these terms.

In short, a design is created, the PCB/PWB is made, components are added, and presto! A CCA is born. Each stage is critical, and understanding the terminology allows for better communication and clarity throughout the entire process.

Why Does This Matter? Practical Applications

6. Where This Knowledge Comes in Handy

Okay, so now you know the difference (or, at least, the potential difference) between a PCB, PWB, and CCA. But why does this matter? In what real-world situations would this knowledge be useful? Well, quite a few, actually! For engineers, designers, and manufacturers, precise terminology is essential for clear communication. When ordering components, specifying manufacturing processes, or troubleshooting problems, knowing the correct term can prevent misunderstandings and costly errors.

For example, imagine you're ordering a batch of circuit boards. If you simply say "I need PCBs," the manufacturer might assume you want bare boards. But if you need fully populated boards, you'd better specify "CCAs." Similarly, if you're working with legacy systems or older documentation, understanding the term PWB can help you interpret technical specifications and diagrams correctly.

Even if you're not a professional engineer, understanding these terms can be helpful when troubleshooting your own electronics. If you're trying to repair a broken gadget, knowing that the CCA is the fully assembled board can help you identify the components that need to be replaced. Additionally, if you're interested in electronics as a hobby, understanding the different stages of circuit board manufacturing can be fascinating and empowering.

Ultimately, knowing the difference between PCB, PWB, and CCA is about more than just jargon. It's about having a deeper understanding of how electronics work and how they're made. And that's a pretty valuable skill in our increasingly tech-driven world. It is more than just knowing what to call something but rather a better understanding on how the item is constructed.