Inspirating Tips About Why Is 3-phase More Beneficial Than Single-phase

Why Is 3 Phase Better Than Single » Wiring Work

Unlocking the Power of Three

1. Understanding the Basics

Ever wondered why massive factories and sprawling commercial buildings don't just plug into a regular wall socket like your toaster? It all boils down to efficiency and power delivery. That's where the difference between single-phase and 3-phase electricity becomes incredibly important. Imagine single-phase as a lone delivery truck trying to haul all the goods to a city. It can get the job done, but it's going to take a lot of trips and a whole lot of effort.

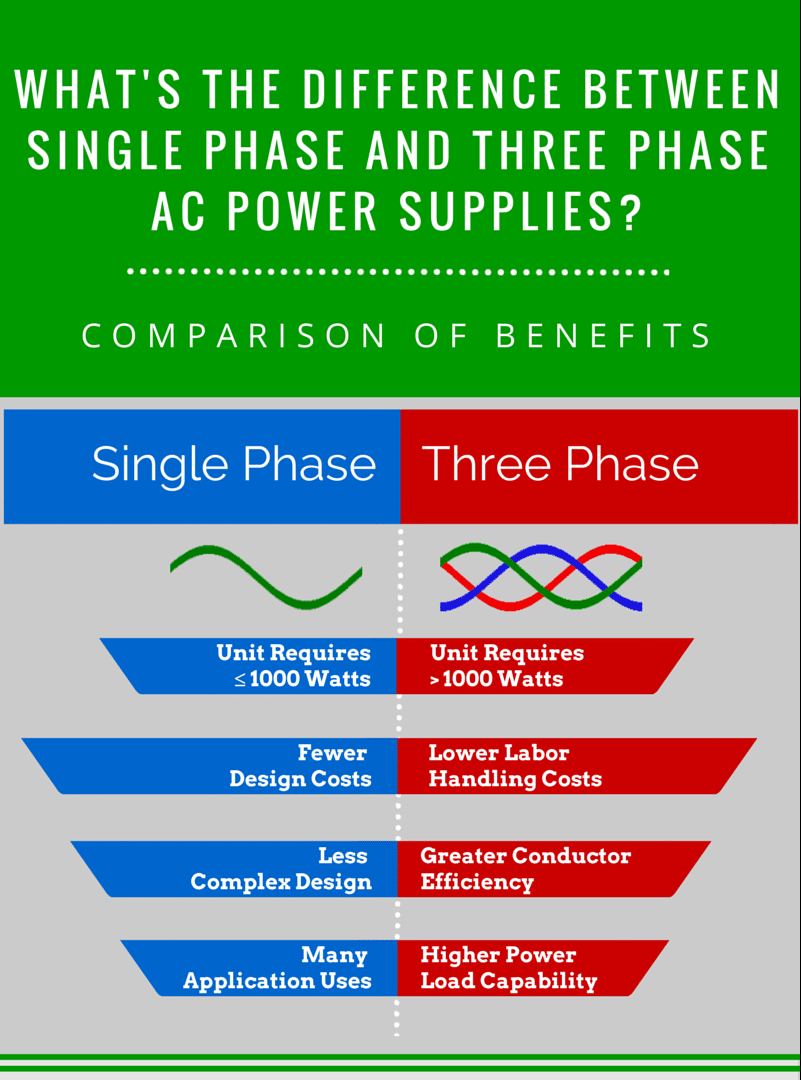

Now, picture 3-phase as three synchronized trucks working together to deliver those same goods. They can carry significantly more, and do it much more smoothly. The "phase" in electricity refers to the number of alternating current (AC) waveforms delivered. Single-phase has one, while 3-phase has, you guessed it, three. These three waveforms are offset from each other, creating a constant and more powerful delivery of electricity. Think of it like a well-coordinated dance, where each dancer seamlessly passes the energy baton to the next.

The keyword phrase, "Why is 3-phase more beneficial than single-phase," highlights this key advantage. It's about the streamlined process and the reduced strain on the electrical system as a whole. Single-phase electricity, while perfectly adequate for homes and smaller appliances, struggles to efficiently power the heavy-duty equipment found in industrial settings. It simply wasn't designed for that kind of workload.

So, the next time you're near a large industrial complex or a high-rise, remember those synchronized trucks and the graceful dance of 3-phase power, tirelessly keeping everything running smoothly. It's the unsung hero of modern industry!

ThreePhase Installation Design A Comprehensive Guide

Smooth Operator

2. Consistent Power Delivery

One of the biggest advantages of 3-phase power over single-phase is its consistent power delivery. Single-phase power pulsates, meaning the power delivered fluctuates 120 times per second, dropping to zero between peaks. While you might not notice it with your lamp, this pulsation can cause vibrations and inefficiencies in motors and other equipment. That slight wobble or hum you sometimes hear? It could be a symptom of single-phase struggles.

With 3-phase power, those three waveforms overlap, resulting in a much smoother and more consistent power supply. Its like having three people pushing a merry-go-round instead of just one — it spins much more evenly. This constant power reduces stress on equipment, leading to longer lifespans and fewer breakdowns. Less maintenance equals more uptime, which is crucial for businesses relying on heavy machinery.

Think of it like this: a car engine with twelve cylinders runs much smoother than one with only four. It's all about the even distribution of power and the reduction of those jarring jolts. That's precisely what 3-phase electricity brings to the table — a smooth, reliable flow of energy that keeps things humming along efficiently.

The consistent nature of 3-phase power translates directly into cost savings and improved performance. Reduced wear and tear, increased efficiency, and minimal downtime all contribute to a healthier bottom line for businesses that rely on it. It's a win-win situation, driven by the simple principle of consistent power delivery.

Smaller Wires, Bigger Impact

3. Less Copper, More Power

Believe it or not, 3-phase systems are actually more economical in terms of wiring requirements compared to single-phase systems delivering the same amount of power. This might sound counterintuitive, but it's true! Because 3-phase systems distribute the power across three conductors instead of one, you can use smaller gauge wires to achieve the same power output.

Smaller wires mean less copper (or aluminum), which translates directly into lower material costs. Considering the sheer amount of wiring needed in large industrial facilities, this difference can be significant. It's like choosing to ship your goods in several smaller boxes instead of one giant, unwieldy crate — you end up using less packaging overall.

Beyond the initial cost savings, smaller wires are also easier to work with and install. They're more flexible and less cumbersome, making the installation process quicker and less labor-intensive. This reduces the overall project costs and minimizes potential delays. Its a win-win situation for everyone involved.

Think about the implications for large-scale infrastructure projects. Reduced material costs, easier installation, and improved overall efficiency all contribute to making 3-phase systems a far more economically sound choice for powering our modern world. It's a testament to the ingenuity of electrical engineering that we can achieve so much with so little.

Why Is 3 Phase Better Than Single » Wiring Work

Motor Mastery

4. The Workhorse of Industry

When it comes to powering heavy machinery, 3-phase motors are the undisputed champions. They're simpler in design, more efficient, and more robust than their single-phase counterparts. Imagine a team of horses pulling a heavy load. A single horse would struggle and quickly tire, while a team of three can distribute the effort and keep going strong. That's the essence of a 3-phase motor.

Single-phase motors often require additional components, such as capacitors, to get them started. These components can be prone to failure and reduce the overall efficiency of the motor. In contrast, 3-phase motors are self-starting and require minimal auxiliary components. This simplicity translates into greater reliability and longer lifespan. They just keep on going, and going, and going...

Furthermore, 3-phase motors typically have higher torque (rotational force) than single-phase motors of the same size. This makes them ideal for applications that require significant power and the ability to handle heavy loads. Think of it as having a stronger grip — 3-phase motors can start and stop with greater ease and precision, making them perfect for everything from conveyor belts to heavy machinery.

The widespread adoption of 3-phase motors in industrial settings is a testament to their superior performance and reliability. They're the workhorses that keep our factories running, our production lines moving, and our world powered. So, next time you see a massive piece of machinery in action, remember the unsung hero behind it all — the mighty 3-phase motor.

The Future is Three

5. Efficiency for a Greener Planet

As we strive for a more sustainable future, the efficiency of our electrical systems becomes increasingly important. Because 3-phase power is inherently more efficient than single-phase, its widespread adoption can contribute to significant energy savings and a reduced carbon footprint. Every watt saved is a watt less energy that needs to be generated, which in turn reduces the strain on our natural resources.

Imagine a world where all industrial facilities and commercial buildings are powered by highly efficient 3-phase systems. The cumulative effect of these individual improvements would be enormous, leading to a significant reduction in greenhouse gas emissions and a cleaner, healthier environment for everyone. It's a small change with the potential for a massive impact.

Furthermore, the longer lifespan and reduced maintenance requirements of 3-phase equipment also contribute to sustainability. Fewer breakdowns mean fewer replacement parts, less waste, and a reduced demand for raw materials. It's a holistic approach to sustainability that considers the entire lifecycle of the equipment.

As technology continues to advance, we can expect to see even greater improvements in the efficiency and performance of 3-phase systems. From smart grids that optimize power distribution to advanced motor control technologies, the future of electricity is undoubtedly three-phase. It's a smart investment in our planet and a key component of a sustainable future.