Beautiful Work Tips About How To Make PWM With Transistor

New Simplest PWM Generator WITHOUT 555 Timer IC (improved Version Using

Unlocking the Power of Pulse Width Modulation

1. What is PWM and Why Should You Care?

Pulse Width Modulation, or PWM, might sound like something out of a sci-fi movie, but it's actually a pretty neat technique used to control the average power delivered to an electrical device. Think of it like this: instead of constantly blasting a lightbulb with full power, you rapidly switch it on and off. By varying the amount of time the light is on versus off (the "pulse width"), you can dim or brighten it! That's the core idea behind PWM, and it's used in everything from controlling motor speeds to adjusting LED brightness. The beauty of PWM is that it's efficient, allows for fine-grained control, and is relatively simple to implement, especially using our trusty friend, the transistor.

Imagine you're trying to control the speed of a small fan. A simple voltage divider might work, but it wastes a lot of energy as heat. PWM, on the other hand, quickly switches the power on and off. When the power is on, the fan spins. When it's off, it coasts. The longer the power is on in each cycle, the faster the fan spins. This on-off approach minimizes energy loss and gives you precise control over the fan's speed. Pretty cool, right? This principle extends far beyond just fans; it's used in countless applications where precise power control is needed.

Why use a transistor for this task, you might ask? Well, transistors act like electronic switches. They can rapidly turn a circuit on and off, making them perfect for the fast switching required by PWM. They're also relatively inexpensive and easy to incorporate into a circuit. Without transistors, implementing PWM would be significantly more complex and less efficient. So, hats off to the transistor the unsung hero of countless electronic devices!

And here's a little secret: using PWM can even extend the lifespan of your devices! By avoiding constant full power operation, you can reduce wear and tear on components, leading to a longer and healthier life for your gadgets. Think of it as giving your electronics a regular spa day. Now, let's dive into the actual process of creating PWM with a transistor, shall we?

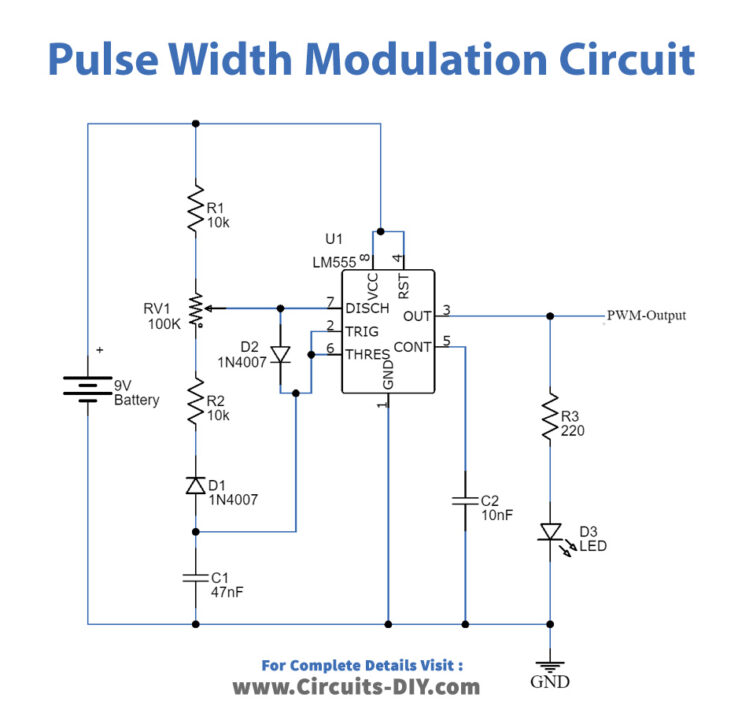

Pulse Width Modulation (PWM) Circuit

Building Blocks

2. Gathering Your Supplies

Before we get our hands dirty (electronically speaking, of course!), let's gather the necessary components. You'll need a transistor (an NPN transistor like a 2N3904 is a common choice), a resistor (the value will depend on your specific circuit, but something in the range of 1k to 10k is a good starting point), a signal source (like a microcontroller or even a function generator if you have one), a power supply, and the device you want to control with PWM (an LED, a small motor, etc.).

Think of the transistor as our bouncer for the electrical party. The resistor acts as a gatekeeper, controlling the flow of electricity to the transistor's base. The signal source is the DJ, telling the bouncer when to open and close the door. The power supply provides the energy for the party, and the controlled device is the guest of honor, enjoying the ambiance created by the precisely controlled electricity.

Choosing the right transistor is crucial. Make sure it can handle the voltage and current requirements of your device. Consult the transistor's datasheet to determine its maximum ratings. Exceeding these ratings can lead to catastrophic failure and nobody wants that! It's like trying to fit a sumo wrestler into a Smart Car; it just won't end well.

Don't forget some breadboard or prototyping board to assemble your circuit! It's like your electronic playground. It allows you to quickly connect the components and test your circuit without soldering. Breadboards are invaluable for experimenting and learning. So, gather your supplies, double-check your component values, and let's get ready to build!

Wiring It Up

3. Connecting the Dots (Electronically)

Now for the fun part: connecting everything together! This is where the magic happens. The circuit itself is fairly straightforward. The base of the transistor is connected to the signal source through the resistor. The collector of the transistor is connected to the positive terminal of the power supply, and the device you want to control (e.g., an LED with a current-limiting resistor) is connected between the transistor's collector and the power supply. The emitter of the transistor is connected to ground.

Imagine the transistor as a water valve. The signal from the microcontroller is like your hand turning the valve on and off. The resistor is like a flow regulator, preventing you from flooding the system. The power supply is the water source, and the LED is the thing you want to water! So, connect everything carefully according to the diagram and remember to double-check your connections.

It's important to note that the resistor in the base circuit is crucial. Without it, you could overload the transistor and potentially damage it. This resistor limits the current flowing into the base, protecting the transistor from excessive current flow. Think of it as a bodyguard for your transistor, preventing it from getting mobbed by electrons.

Before applying power, triple-check your connections. A misplaced wire or a wrong component value can lead to unexpected results, including damaged components. It's always better to be safe than sorry! So, take your time, be meticulous, and double-check everything before flipping the switch. Your electronics (and your sanity) will thank you.

Generating the PWM Signal

4. Microcontroller Magic

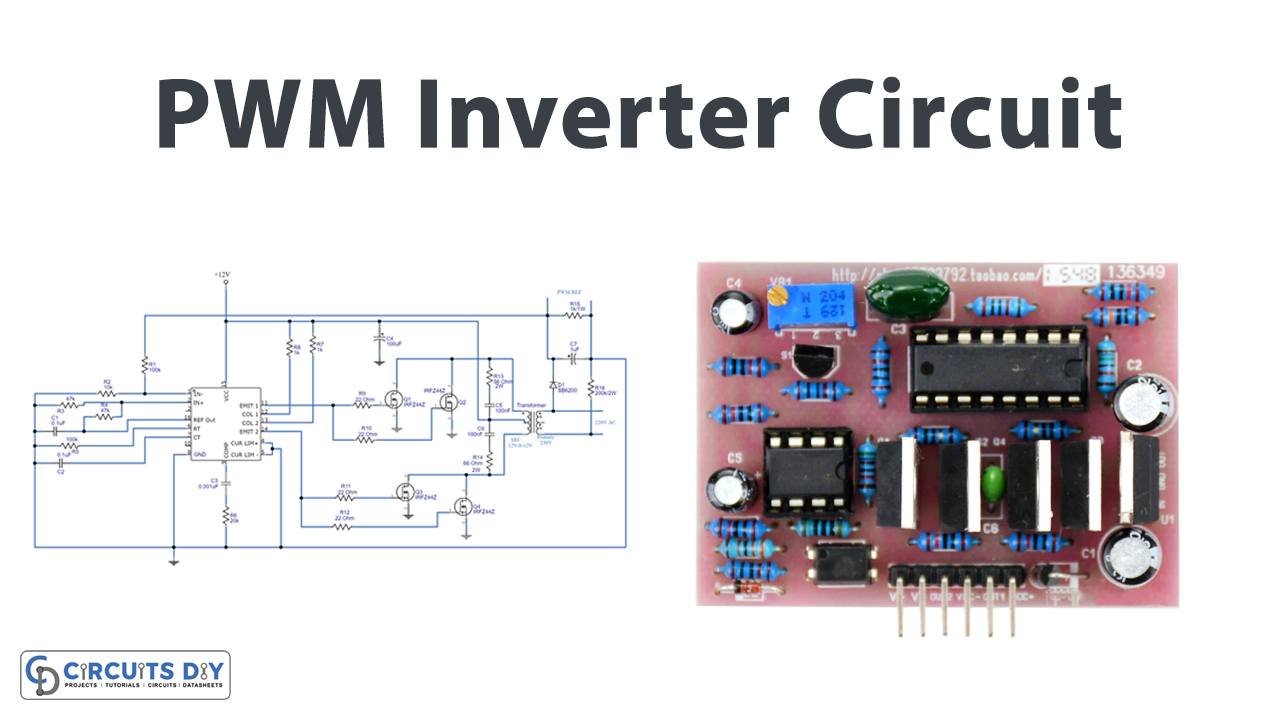

The heart of our PWM system is the signal source, which generates the pulse width modulated signal. A microcontroller, like an Arduino, is perfect for this task. Microcontrollers have built-in PWM capabilities, making it easy to generate precise PWM signals. You can control the frequency and duty cycle of the PWM signal using simple programming commands.

Think of the microcontroller as the conductor of an orchestra. It tells each instrument (in this case, the transistor) when to play and for how long. The frequency of the PWM signal determines how often the transistor switches on and off, while the duty cycle determines the percentage of time the transistor is on during each cycle. This precise control allows you to fine-tune the power delivered to your device.

If you're using an Arduino, you can use the `analogWrite()` function to generate PWM signals on specific pins. The `analogWrite()` function takes a value between 0 and 255, which represents the duty cycle. A value of 0 corresponds to 0% duty cycle (always off), while a value of 255 corresponds to 100% duty cycle (always on). Experiment with different values to see how they affect the brightness of your LED or the speed of your motor.

Don't have a microcontroller? No problem! You can also use a function generator to create a PWM signal. Function generators are versatile instruments that can generate a variety of waveforms, including square waves with adjustable duty cycles. Simply connect the output of the function generator to the base of the transistor (through the resistor, of course!), and adjust the frequency and duty cycle to your liking. It's like having a mini-laboratory right at your fingertips!

Testing and Tweaking

5. Getting the Perfect Pulse

Once you've built the circuit and generated the PWM signal, it's time to test and tweak it. Observe the behavior of your controlled device. If you're using an LED, adjust the duty cycle of the PWM signal and observe how the brightness changes. If you're using a motor, adjust the duty cycle and observe how the speed changes. Use a multimeter to measure the voltage across your controlled device to get a quantitative measurement of the average power being delivered.

Think of this stage as tuning a musical instrument. You're listening carefully to the sound and making adjustments until you achieve the desired tone. Similarly, you're observing the behavior of your device and making adjustments to the PWM signal until you achieve the desired performance. This is where the art of electronics meets the science!

Pay attention to the frequency of the PWM signal. A very low frequency might cause flickering in an LED or jerky movement in a motor. A very high frequency might exceed the switching capabilities of the transistor, leading to inefficiencies. Experiment with different frequencies to find the sweet spot for your application. This is like finding the perfect tempo for a song too slow, and it drags; too fast, and it's a blur.

If you're experiencing unexpected behavior, double-check your circuit connections, component values, and PWM signal parameters. Use an oscilloscope to visualize the PWM signal and ensure that it's clean and stable. Troubleshooting is a crucial part of the learning process. Don't be afraid to experiment and learn from your mistakes. After all, even the most experienced engineers make mistakes from time to time. The key is to learn from them and keep moving forward!