Real Info About What Is The Function Of Bill Material

Understanding the Bill of Material

1. What a Bill of Material Actually Does

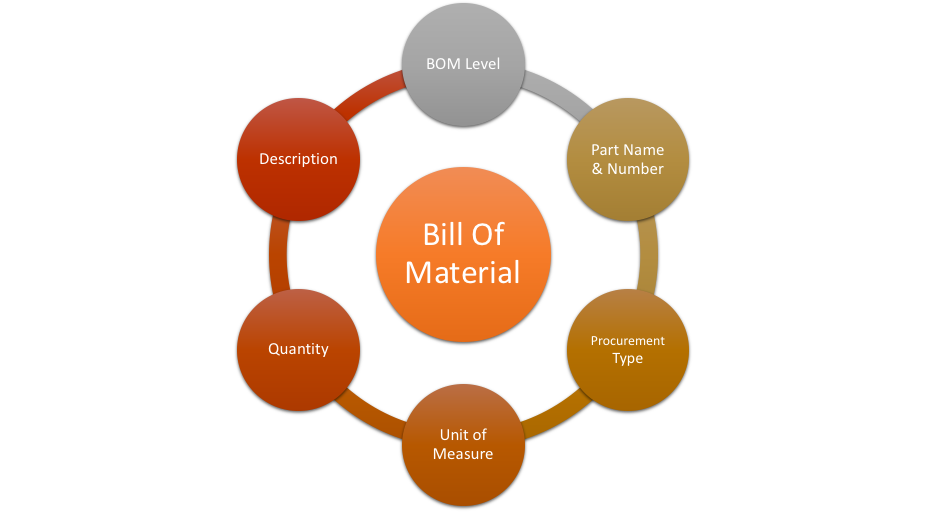

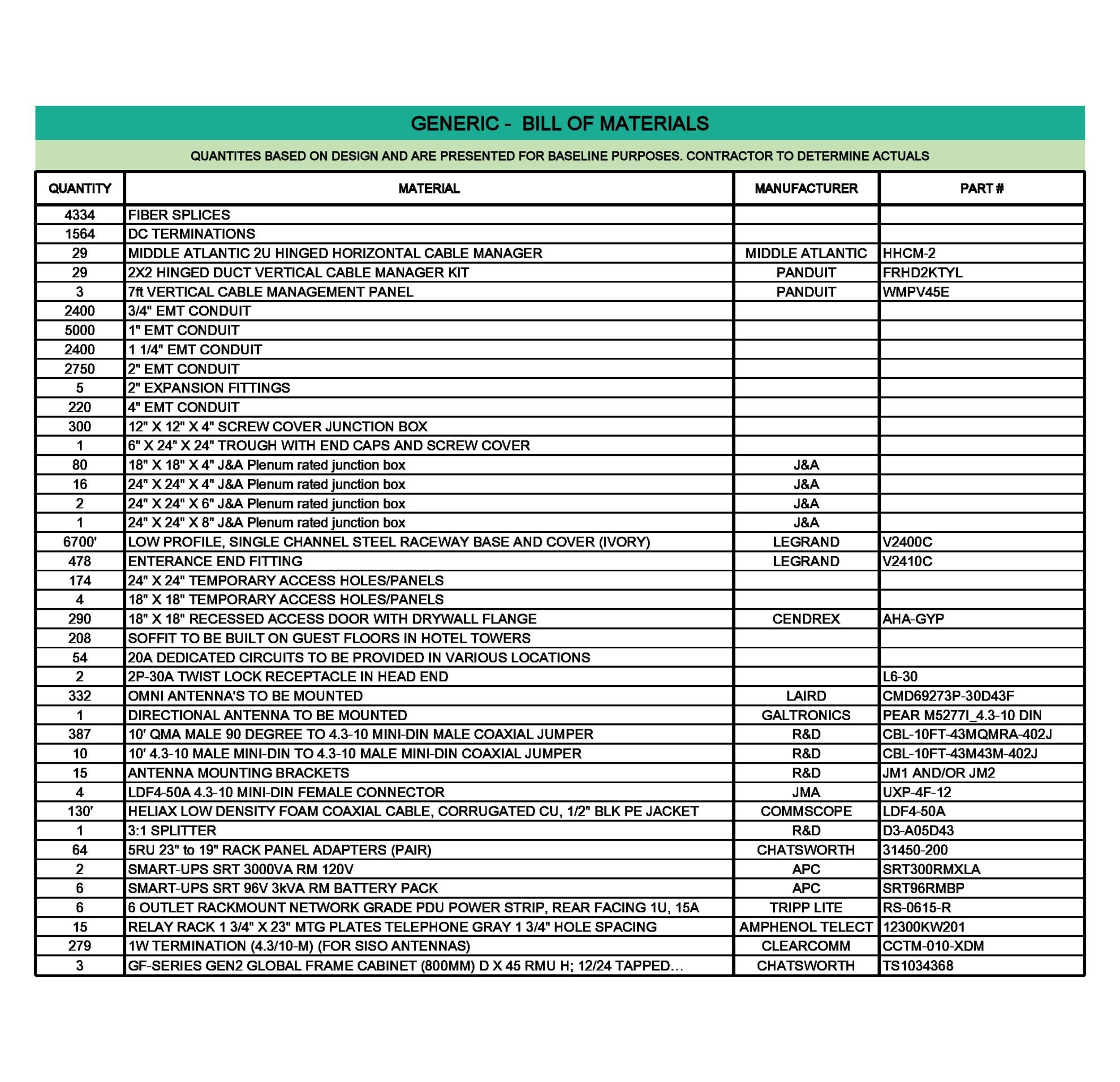

Ever wondered how manufacturers keep track of all the bits and pieces that go into creating a product? That's where the Bill of Material (BOM) comes in. Think of it as a super-detailed recipe for making, say, a bicycle. It's not just a random list of parts; it's a structured inventory of everything required, from the frame and wheels down to the tiniest bolt and washer. It outlines what you need, how much you need, and sometimes even where you get it from. In essence, its the DNA of a product, laid out in meticulous detail.

But the function of a BOM isn't just about inventory management, although that's certainly a big part of it. It's the central nervous system for production planning, cost estimation, and even compliance. Without a solid BOM, you're essentially flying blind. Imagine trying to bake a cake without knowing how much flour you need — disaster, right? The BOM prevents manufacturing disasters by providing a clear roadmap for the entire production process.

And let's be honest, in today's complex supply chains, a well-maintained BOM is absolutely essential. It connects engineering, procurement, manufacturing, and even sales. It ensures everyone is on the same page, using the same information. It's a vital tool for improving efficiency, reducing errors, and ultimately, delivering a quality product on time and within budget. It is the central source of truth.

Ultimately, the function of a BOM extends beyond simply listing parts. It orchestrates the entire product lifecycle, ensuring everything from design to delivery runs smoothly. It's the unsung hero of manufacturing, working quietly behind the scenes to make sure your bicycle (or whatever product we're making) gets built correctly.

Cara Membuat Bill Of Material

Beyond the Basics

2. How BOMs Streamline Processes

Okay, so we know the BOM lists all the parts. But let's dig a little deeper into its day-to-day duties. One critical function of a BOM is facilitating accurate cost calculations. By itemizing every component, along with its cost, manufacturers can precisely determine the overall cost of a product. This is crucial for pricing decisions, profitability analysis, and budget forecasting. Without a clear understanding of the cost breakdown, businesses could be making decisions based on inaccurate information, potentially leading to financial trouble. And nobody wants that.

Then there's the role the BOM plays in procurement. It's a purchasing department's best friend. The BOM provides a clear list of materials needed, allowing buyers to order the right quantities from the right suppliers at the right time. This minimizes the risk of stockouts, which can halt production and delay deliveries. Conversely, it also helps avoid overstocking, which ties up capital and increases storage costs. A well-maintained BOM is a valuable weapon in the battle against inefficiencies and waste.

Furthermore, the BOM serves as a key communication tool between different departments. Engineers, manufacturers, and quality control teams all rely on the BOM for product specifications and assembly instructions. It ensures everyone is working from the same blueprint, minimizing misunderstandings and errors. And in a world where miscommunication can lead to costly mistakes, that's a big win.

The power of a BOM extends even to maintenance and repair operations. When products need servicing, the BOM provides a ready reference for replacement parts. This speeds up the repair process, reduces downtime, and improves customer satisfaction. Think of it as having a detailed map to navigate the inner workings of a product, ensuring repairs are quick, efficient, and effective. This becomes exceptionally useful in products with a long lifespan.

![Free Printable Bill Of Material Form Templates [PDF, Excel] Free Printable Bill Of Material Form Templates [PDF, Excel]](https://www.typecalendar.com/wp-content/uploads/2023/05/Bill-of-Material-1-1200x675.jpg)

Different Flavors of BOMs

3. Choosing the Right BOM for the Job

Believe it or not, not all BOMs are created equal. There are different types tailored to specific needs. The two main varieties are the Engineering Bill of Material (EBOM) and the Manufacturing Bill of Material (MBOM). Think of them as two slightly different versions of the same recipe, adjusted for different cooks in the kitchen.

The EBOM, as the name suggests, focuses on the design and engineering aspects of a product. It lists all the parts as designed by the engineering team, often including raw materials, subassemblies, and even software components. Its a comprehensive view of the product's architecture, used for design validation, prototyping, and initial cost estimation. It often contains items that aren't directly involved in the manufacturing process, like design specifications and testing parameters.

On the other hand, the MBOM is geared towards the actual manufacturing process. It outlines the parts and assemblies needed to build the product, along with the specific steps and resources required. The MBOM considers factors like manufacturing processes, assembly sequences, and required tools. It's often more detailed than the EBOM, including information like component lead times, supplier details, and work instructions. It is what the manufacturing team uses to assemble the product.

The key difference lies in their purpose. The EBOM is design-centric, while the MBOM is production-centric. Choosing the right type of BOM depends on the specific task at hand. Using an EBOM for manufacturing could lead to confusion and inefficiencies, while using an MBOM for design might lack critical engineering information. In a perfect world, the EBOM and MBOM are closely linked, ensuring a seamless flow of information from design to manufacturing.

Bill Of Materials Key Components, Types & More TAG Samurai

The BOM and ERP

4. How Integration Amplifies Functionality

In the modern manufacturing landscape, the Bill of Material rarely exists in isolation. It's typically integrated with an Enterprise Resource Planning (ERP) system, creating a powerful synergy that streamlines operations and improves decision-making. Think of the ERP system as the central nervous system of a business, and the BOM as a crucial organ providing vital information.

Integrating the BOM with ERP allows for real-time tracking of inventory levels, production progress, and costs. Changes to the BOM, such as material substitutions or design modifications, are automatically reflected in the ERP system, ensuring everyone is working with the most up-to-date information. This eliminates data silos and reduces the risk of errors caused by outdated spreadsheets or manual data entry.

Furthermore, ERP integration enables better demand forecasting and production planning. By analyzing sales data and inventory levels, the ERP system can use the BOM to predict future material requirements and optimize production schedules. This helps manufacturers avoid stockouts, reduce lead times, and improve customer satisfaction. Its like having a crystal ball that allows you to anticipate future needs and plan accordingly.

And let's not forget the role BOM-ERP integration plays in compliance and regulatory reporting. The BOM provides a detailed record of all materials used in a product, which is essential for meeting industry regulations and environmental standards. The ERP system can then generate reports that demonstrate compliance, helping manufacturers avoid costly fines and maintain a positive reputation. It's a critical tool for ensuring that products are safe, reliable, and meet all applicable legal requirements.

Future of the BOM

5. Emerging Trends and Technologies

The Bill of Material isn't a static document; it's constantly evolving to meet the changing needs of the manufacturing industry. Emerging trends and technologies are shaping the future of the BOM, making it more dynamic, intelligent, and integrated than ever before.

One key trend is the move towards digital thread and digital twin technologies. The digital thread connects all aspects of the product lifecycle, from design and engineering to manufacturing and service, creating a continuous flow of information. The digital twin is a virtual representation of a physical product, allowing manufacturers to simulate performance, optimize designs, and predict maintenance needs. The BOM plays a central role in both of these technologies, providing the foundational data for creating a comprehensive digital representation of the product.

Another emerging trend is the use of artificial intelligence (AI) and machine learning (ML) to optimize BOM management. AI and ML algorithms can analyze BOM data to identify patterns, predict material shortages, and optimize production schedules. They can also automate tasks like BOM creation, validation, and version control, freeing up human resources for more strategic activities. Its like having a super-smart assistant that can handle the tedious aspects of BOM management, allowing you to focus on the bigger picture.

And let's not forget the increasing importance of sustainability. Consumers are demanding more environmentally friendly products, and manufacturers are responding by incorporating sustainable materials and processes into their designs. The BOM is playing a key role in this transition, providing a way to track the environmental impact of each component and identify opportunities for improvement. From recycled materials to biodegradable packaging, the BOM is helping manufacturers create products that are both high-performing and environmentally responsible.

FAQ

6. Your Burning BOM Questions Answered

Still scratching your head about BOMs? Don't worry, you're not alone! Here are some frequently asked questions to clear up any lingering confusion.

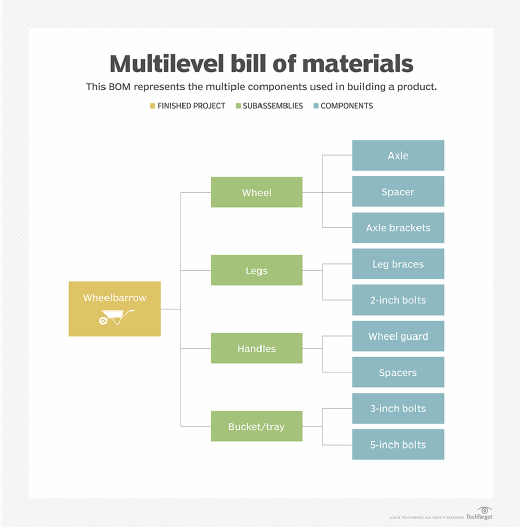

Q: What's the difference between a single-level BOM and a multi-level BOM?A: A single-level BOM lists only the components directly used to assemble a product. A multi-level BOM, also known as an indented BOM, shows the hierarchical relationship between components and subassemblies. Think of it like a family tree for your product!

Q: How often should I update my BOM?A: As often as necessary! Any change to the product design, manufacturing process, or materials should trigger a BOM update. It's better to be proactive than reactive when it comes to BOM maintenance. This will keep your data accurate and prevent errors further down the line.

Q: Can I use a spreadsheet for my BOM?A: While possible for very simple products, spreadsheets quickly become unwieldy and prone to errors as complexity increases. Dedicated BOM management software or an integrated ERP system is highly recommended for anything beyond the basics. It all depends on the scalability of your product.