Favorite Info About Which Is Better ACSR Or AAAC

ACSR Vs. AAAC AAC Which Overhead Conductor Is Best For Your

ACSR vs. AAAC

1. Decoding the Acronyms

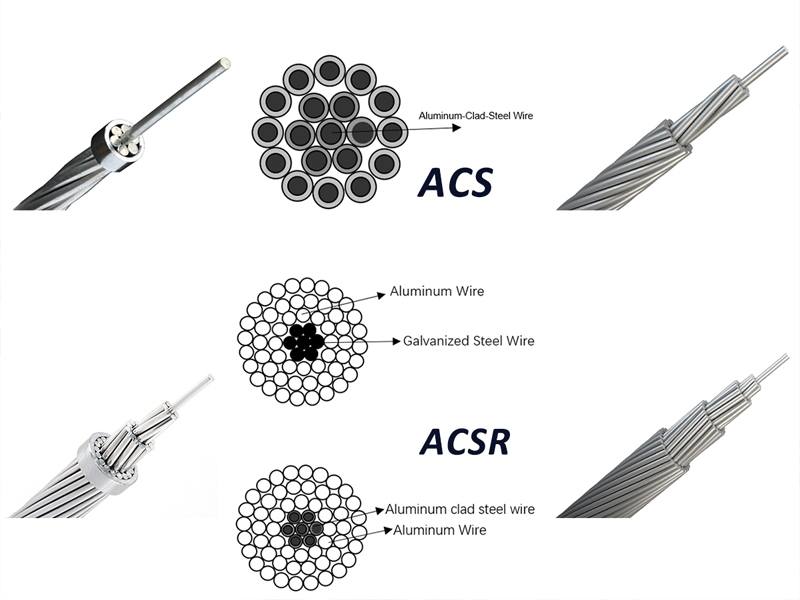

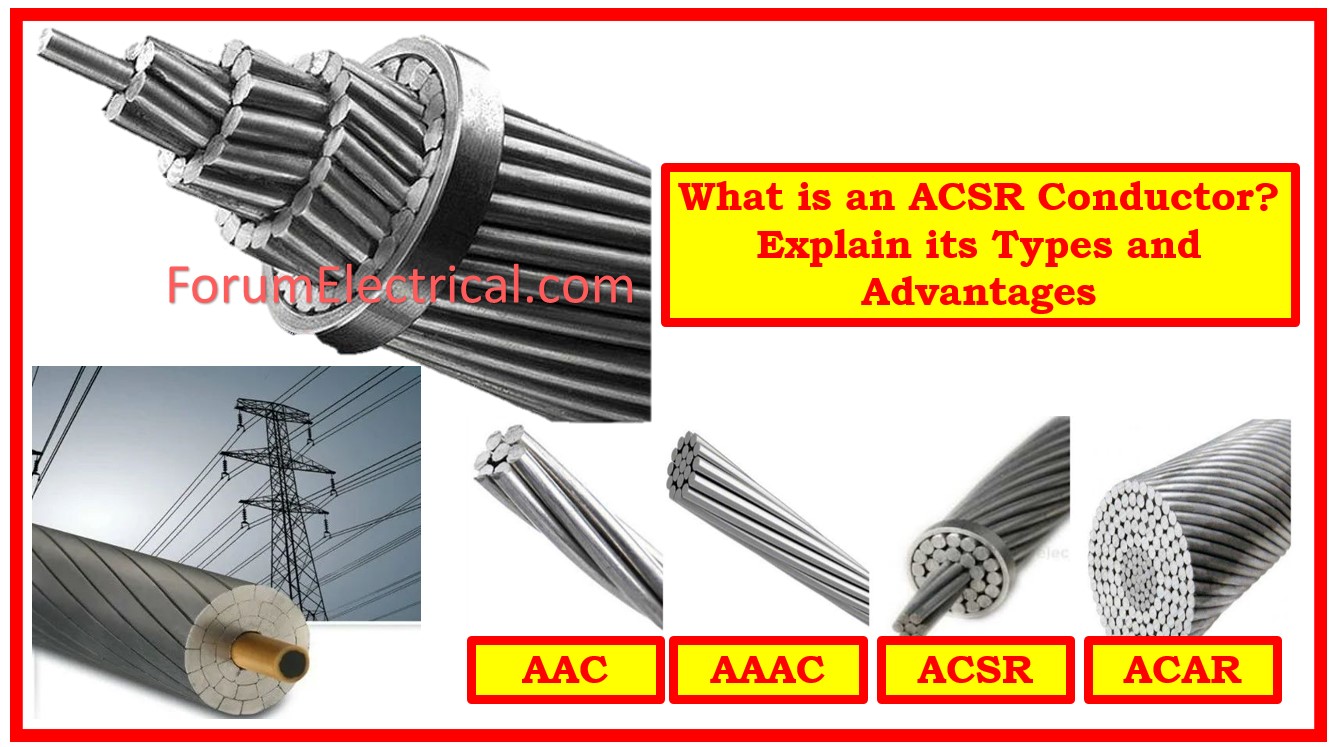

Alright, let's face it, ACSR and AAAC sound like robot names from a low-budget sci-fi movie. But fear not! We're diving into the world of electrical conductors, specifically those used in overhead power transmission. ACSR stands for Aluminum Conductor Steel Reinforced, while AAAC means All Aluminum Alloy Conductor. Basically, we're comparing a conductor that's a blend of aluminum and steel with one that's purely aluminum alloy. Think of it like choosing between a burger with bacon (ACSR the steel is like the bacon, adding strength) and a leaner, all-beef burger (AAAC). Both get the job done, but they have different strengths and weaknesses.

So, why all the fuss about these conductors? Well, they're the unsung heroes of our electrical grid, carrying the power that keeps our lights on and our Netflix streaming. Choosing the right one is crucial for efficiency, cost-effectiveness, and overall reliability of the power grid. Think of the implications — a poor choice could lead to power outages, higher energy bills, or even safety hazards. No pressure, right?

The key difference lies in their composition and how that affects their properties. ACSR, with its steel core, offers high tensile strength, which means it can withstand greater mechanical stress. AAAC, on the other hand, is lighter and has better corrosion resistance. Understanding these nuances is key to making an informed decision for specific applications.

Ultimately, the 'better' conductor isn't a one-size-fits-all answer. It depends heavily on the specific needs of the project, the environmental conditions, and the budget. But don't worry, we'll break it all down in plain English (with a touch of humor, of course) so you can make the right choice. Let's get wired!

The Complete Guide On ACSR Conductors Types, Properties, And Its

Strength vs. Conductivity

2. Tug-of-War

Here's where ACSR flexes its muscles, literally. The steel core in ACSR provides exceptional tensile strength. This means it can handle longer spans between support towers without sagging excessively. Think of it like a weightlifter — it can bear a heavier load. This is particularly important in areas with high winds, heavy ice loads, or long distances between support structures. If you need a conductor that can really hold its own, ACSR is often the go-to choice.

AAAC, while strong, doesn't quite match the brute strength of ACSR. It's like a marathon runner — it has endurance, but not the same raw power. However, don't underestimate AAAC's strength. It's still capable of handling typical overhead line conditions, and its lighter weight can be an advantage in certain situations. Plus, advancements in aluminum alloy technology are constantly improving the strength of AAAC conductors.

Think about it this way: if you're building a bridge across a wide river, you'd want strong steel cables. Similarly, for long-span power lines in challenging environments, ACSR is often the preferred choice. But if you're building a shorter bridge or one in a less demanding environment, a lighter, more flexible material might be sufficient.

The decision really boils down to the specific requirements of the project. How far apart are the support towers? What's the expected wind and ice load? These are the kinds of questions you need to ask to determine which conductor has the necessary muscle.

3. Current Affairs

Now, let's talk about how well these conductors actually conduct electricity. This is where AAAC starts to shine. Because it's made entirely of aluminum alloy, it generally has better electrical conductivity than ACSR. This means it can carry more current with less energy loss. Think of it like a super-efficient engine — it gets you further on less fuel.

ACSR, with its steel core, has a lower overall conductivity because steel isn't as good of a conductor as aluminum. However, the steel core is essential for providing the necessary strength. It's a trade-off — you sacrifice some conductivity for increased mechanical strength. This is why choosing the right conductor is all about finding the optimal balance between these two properties.

The higher conductivity of AAAC can lead to lower line losses and improved overall efficiency of the power grid. This can translate to lower energy bills and reduced environmental impact. In a world increasingly focused on sustainability, efficiency is a major selling point.

So, if you're prioritizing energy efficiency and minimizing losses, AAAC is often the better choice. But remember, you still need to consider the mechanical requirements of the project. It's all about finding the sweet spot where strength and conductivity meet.

Weathering the Storm

4. Rust Never Sleeps

Corrosion is the enemy of all things metal. It can weaken conductors, reduce their conductivity, and ultimately lead to failure. And when it comes to corrosion resistance, AAAC generally has the upper hand. Aluminum alloys are naturally resistant to corrosion, especially in most atmospheric conditions. They form a protective oxide layer that shields the underlying metal from further degradation.

ACSR, on the other hand, is more susceptible to corrosion, particularly where the steel core is exposed. This is especially true in coastal areas with high salt concentrations or in industrial areas with acidic pollution. Corrosion can weaken the steel core, reducing the overall strength of the conductor.

To mitigate corrosion in ACSR conductors, various protective measures can be taken, such as galvanizing the steel core or applying a grease coating. However, these measures add to the cost and complexity of the installation. Choosing AAAC can often simplify the installation process and reduce long-term maintenance costs.

If you're in an area with harsh environmental conditions, corrosion resistance should be a major consideration. AAAC's superior corrosion resistance can make it a more durable and cost-effective choice in the long run. Think of it like choosing between a stainless-steel appliance and one made of regular steel — the stainless steel will hold up much better in a humid environment.

Cost Considerations

5. Money Talks

Let's be real — money matters. The cost of the conductor is a significant factor in any project. Generally, ACSR is less expensive than AAAC, primarily due to the lower cost of steel compared to aluminum alloy. This can make ACSR an attractive option for projects with tight budgets.

However, it's important to consider the long-term costs as well. While ACSR may have a lower initial cost, it may require more maintenance due to its susceptibility to corrosion. AAAC, with its superior corrosion resistance, can potentially save money in the long run by reducing maintenance and replacement costs.

Another factor to consider is the cost of installation. AAAC conductors are typically lighter than ACSR conductors, which can make them easier and less expensive to install. This can offset some of the higher initial cost of the conductor.

Ultimately, the most cost-effective choice depends on a variety of factors, including the initial cost of the conductor, the cost of installation, the expected maintenance costs, and the lifespan of the project. A thorough cost-benefit analysis is essential to making an informed decision.

Building Better Overhead Lines Comparing AAAC, AAC And ACSR Elka

The Verdict

6. So, Which One Wins? It Depends!

As you can see, there's no clear winner in the ACSR vs. AAAC debate. Both conductors have their strengths and weaknesses. The best choice depends on the specific requirements of the project, the environmental conditions, and the budget.

If you need high tensile strength for long spans or harsh environments, ACSR is often the better choice. If you prioritize energy efficiency and corrosion resistance, AAAC is often the way to go. And if you're on a tight budget, ACSR may be the more affordable option upfront, but consider the long-term maintenance costs.

The key is to carefully evaluate the needs of your project and weigh the pros and cons of each conductor. Consider factors such as span length, wind and ice loads, environmental conditions, energy efficiency requirements, and budget constraints. Consulting with experienced engineers and electrical contractors can also be invaluable in making the right decision.

Think of it like choosing a car. Do you need a powerful truck for hauling heavy loads, or a fuel-efficient sedan for commuting to work? Both cars can get you from point A to point B, but they're designed for different purposes. Similarly, ACSR and AAAC are both excellent conductors, but they're best suited for different applications. Choose wisely, and your power grid will thank you!